Over the weekend, a semester’s worth of work was fired up with wood by a group of advanced art students.

It is a regular tradition for ceramics students since the wood-fired kiln was built in 1995. At the beginning of the semester, a group of ceramics students came together to decide whether to gear up for the firing. It is a gamble–success often depends on factors out of the students’ control. Past years the wood they got was too wet, resulting in a lower firing temperature, and undesired results. This year, they were lucky to get a donation of cottonwood—perfect for the wood kiln.The woodfiring is completely student organized, and the students involved take pride in the process. Working to loud music and eating pizzas fired atop the kiln are a few of their perks. This firing was headed up by Alex Caskey, Phil Hosler, Aaron Shenk, and Casey Diener. Mark Goertzen, a potter with Dick Lehman at the Old Bag factory, gave the students pointers.

At the start of the week, the students cleaned out ash from past years, got the kiln shelves ready. Small objects sometimes get lost in the kiln—a clay dinosaur of former student Paula Dirks was found stuck in a corner. On Wednesday, they spent the day stacking the kiln with cut wood, and then preheated the kiln with a gas torch. Early Thursday morning, Caskey and Shenk started the kiln fire, with a goal of 2200 to 2300ºF.

“We measure the degree with ‘cones,’ a type of ceramic temperature meter designed to melt at a certain temperature,” explained Hosler, pulling out a brick peep-hole. “Past years, we couldn’t get past cone eight, which meant we were about 150 degrees shy from what was needed.”

Between 150 and 200 pieces are being fired this year, but the number varies depending on the size of the works. The four students, along with the help of some other ceramics students, took shifts to keep the fires going throughout the day and night, stopping around 10 or 12 p.m. Friday night. Then, they wait, hoping for the kiln to cool as slowly as possible.

“That’s when the really great colors are created,” said Caskey.

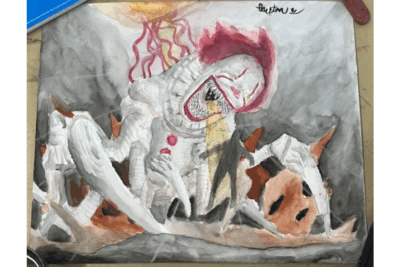

Why put in all the time and work of woodfiring when they could use a regular electric kiln? One reason is that different colors and effects are achieved by the flames and ash than in regular firings. “You can get a more organic look—so much is unpredicable,”said Diener. “It’s a personal aesthetic. Most people don’t appreciate the time, procees or natural look,” added Hosler. But, some of the special glazes achieved won’t be found without woodfiring.

Tuesday afternoon, when the kiln had cooled sufficiently, it was time to see the results.

“In reference to the firing process,” Hosler explained, “I believe it went as smoothly and perfectly as we could have asked for. We hit the temperature we wanted (around 2400 degrees) by around 11 a.m. Friday and held it at that temp for 12 or so hours. The final results varied from piece to piece with some pieces capturing blues and greens from the wood ash, but other pieces came out rough because of unmelted wood ash that was stirred up later on in the firing.”

Many of the woodfired pieces will be on sale at the Student Art Sale. It’s an artistic risk taken with sweet results.